Leayo new generation full frequency precision air conditioning with fluorine pump design

"First, the use of full frequency compressor, reduce energy consumption, improve the overall energy saving rate, while reducing the frequent start and stop of the compressor, improve the overall life of the unit;

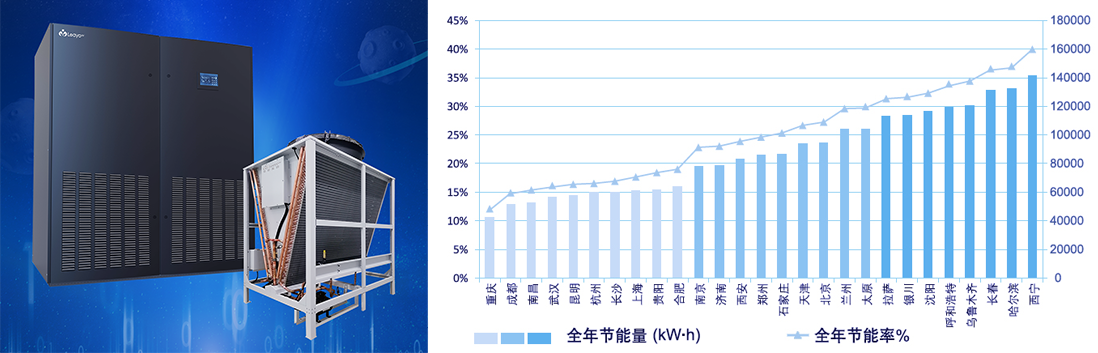

Two, with centrifugal fluorine pump, three operating modes: above 25℃ mechanical refrigeration; 5-25℃ adopts mixed refrigeration, below 5℃ adopts fluorine pump operation mode, annual energy saving up to 40%;

3. Centralized condenser design, V-type heat exchanger design, modular splicing, high efficiency and energy saving while saving space up to 60%;

4, the whole machine adopts efficient EC fan, improve the efficiency of the unit more than 30%;

5, the standard oil design, while ensuring the reliability of the unit, can be matched with extended components to achieve high drop, long pipe worry-free operation;

6, the unit low temperature options and fluorine pump design to achieve reliable operation below minus 40℃;

Seven, intelligent control:

7 "monitor as standard

Temperature and humidity curve real-time feedback unit operating status

The operation and loading of each part of the unit are displayed graphically

Group control status such as rotating backup can be realized

At the same time, it can upload remote Settings, monitor the running status of the unit and store alarm information

8, the use of efficient humidification system;

9. Efficient electric heating;

Ten, a variety of cooling methods optional:

Air-cooled/water-cooled/double-cooled source (air-cooled/water-cooled + chilled water)/dual-cycle integrated fluorine pump

11, a variety of ways to send points optional:

Up air supply/down air supply/Floor sinking air supply